Home › Forums › TinyG › TinyG Feature Requests › Macro Support

- This topic has 6 replies, 2 voices, and was last updated 10 years, 10 months ago by

RodeoClown.

-

AuthorPosts

-

June 30, 2014 at 9:40 pm #6304

RodeoClown

MemberOther CNC software has Macro capabilities.

For example, I can create a custom g-code command that when I fire off that command I can run a prewritten chunk of g-code.

It would be great if TinyG could do this, then I could add ATC to my machine with the 4th axis.

July 12, 2014 at 6:49 pm #6428jlauer

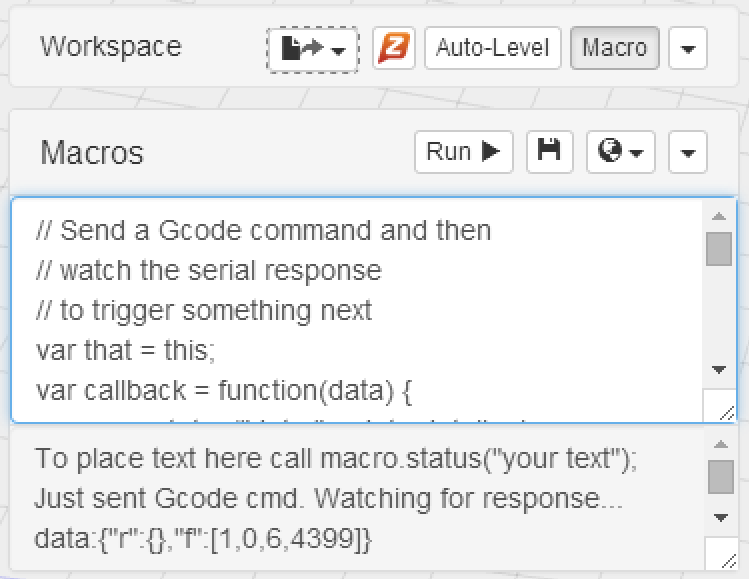

MemberYou are in luck. Just launched a Macro widget inside ChiliPeppr Hardware Fiddle. If you go to the TinyG workspace at http://chilipeppr.com/tinyg you will see the new widget in the Workspace toolbar.

Check out the “Watch Gcode Response” sample script for a really awesome way to see what your Gcode is doing and respond to it.

July 18, 2014 at 1:18 am #6438

July 18, 2014 at 1:18 am #6438RodeoClown

MemberNice work, I am putting some thought into making my own widgets for Chilipeppr. I use a usb microscope for aligning my cutting tip, first aligning the camera to the stock point on what I am cutting and then running g-code to apply an offset so my tip is aligned.

Would be good to make an all in one solution, but may be out of my developmental reach.

July 28, 2014 at 11:23 am #6515jlauer

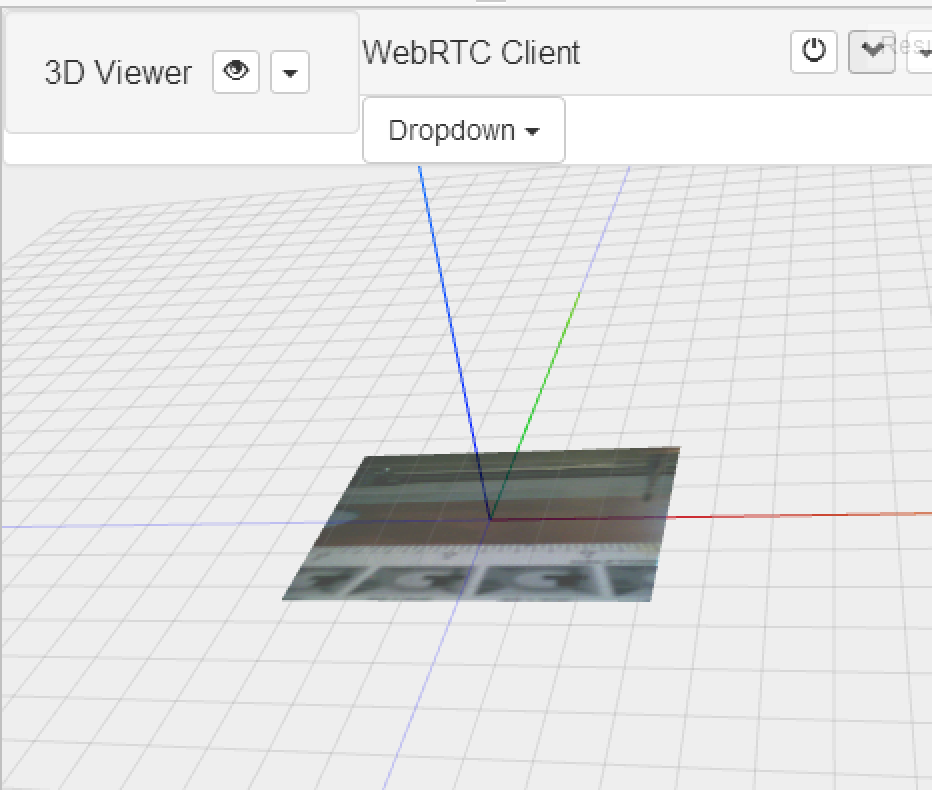

MemberSo, you’ll be geeked by the current work on USB microscopes then. I have two attached to my spindle and I’m 80% there on projecting the video into the 3D Viewer at the correct location. You can check out the work in progress.

Client Widget

http://jsfiddle.net/chilipeppr/k9aXL/Server Widget (Run on multiple machines for more cams)

http://jsfiddle.net/chilipeppr/stpbm/Client Widget Merged with 3D Viewer Test

http://jsfiddle.net/chilipeppr/k789v/ July 30, 2014 at 2:18 am #6522

July 30, 2014 at 2:18 am #6522RodeoClown

MemberThat looks awesome, I never thought of inserting it into the viewer.

How do you have your microscopes mounted? I 3d printed a mount for my spindle, but am going to redesign to work in conjunction with a dust extractor. I actually just bought two new ones that are a lot smaller, so I can mount them closer to the cutting tool. I am impatient and the time it took for me to move from centred on the cam to centred on the tip was like 6 – 7 seconds. Talk about a first world issue.

July 31, 2014 at 12:23 pm #6536jlauer

MemberI mounted them pretty basic right now with tape! However, I was going to mill out some acrylic to better mount them in an exact spot. I bought these on ebay because they were small. http://www.ebay.com/itm/321060396782?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1439.l2649

They’re just ok though. I am having a hard time getting them really close to the spindle due to the height. I may have to put them at an angle which means I’ll have to apply further transformations to them in the 3D viewer to get the image to appear flat.

If you can get the toolhead to align with the video using the control panel I’m not quite done with, then you shouldn’t have to move anything at all due to your offset once you visually line things up.

August 1, 2014 at 3:04 am #6544RodeoClown

MemberHa, they are the same as some of the ones I use. I have them everywhere. One on the drill press, one on the drop saw, one on the mill.

I first did an acrylic mount, but switched to a 3d printed one that was re-enforced with aluminium as I kept bumping it and putting it out of wack.

I found the best approach was to use only one, keep it parallel to the spindle and use an offset. As soon as I introduced angles into it, the height of the tool became an issue. And large tools, like face mills, became impossible to line up.

-

AuthorPosts

- You must be logged in to reply to this topic.